|

ENGINEERING SUPPORT

The success of a mass transfer job depends as much on the quality of the hardware as it does on the quality of the engineering support provided by the supplier. As the members in AMT Pacific has extensive experience in the basic/detailed engineering as well as in the design of tower internals for the refinery and petro-chemical plants, AMT Pacific can assist you in the design of mass transfer system.

AMT Pacific also can supply various kinds of tower internals including the high performance trays and structured packings. Therefore, the superior engineering support in the areas of tower internal selection can be provided by AMT Pacific. For trouble-shooting and debottlenecking mass transfer equipment, it is very important to identify them. This can be achieved by the Gamma ray-scanning and process simulation provided by AMT Pacific.

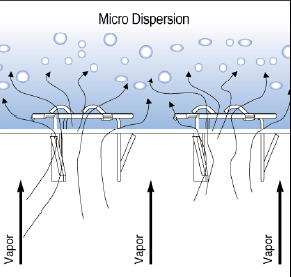

Trays

ADV High Performance Tray Valve(S, SE, SC, SD ..), Sieve, Bubble CapTray

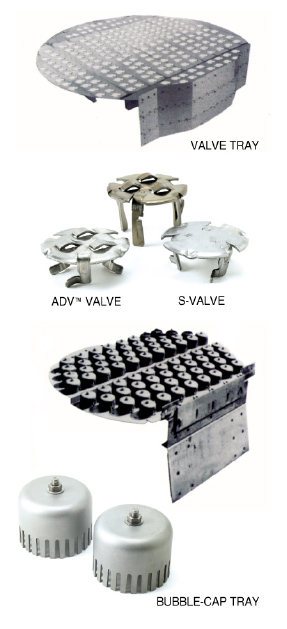

Packings

- Structured Packings(SP-100, SP-220 ..)

- Random Packings(S-Ring, SR+ ..)

- Grid Packings(SG-1 ..)

Packing Internals

- Liquid distributors

- Vapor diffusers

- Two-phase feed distributors

- Collector trays, Chimney trays

- Bed supports & Bed limiter, etc.

ON- SITE SERVICES

AMT Pacific also provide the following services.

- Installation

- Installation Supervision

- Start-up Assistance

ADV™ PINNACLE PERFORMANCE TRAY

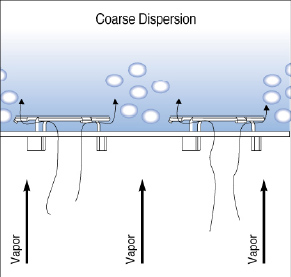

ADV™ Mechanism

|

| CONVENTIONAL VALVE TRAY |

|

| ADV™ TRAY |

Advantages over Conventional Trays

- Up to 40% greater throughput capacity.

- Up to 10% better fractionation efficiency.

- Up to 20% lower pressure drop

- Greater turn down ratio.

- Minimum modifications for debottlenecking.

- Easier field installation of trays.

- Quick payback of debottlenecking costs.

- Lower initial investment for new towers.

Typical Applications

- Oil Refineries

- Crude Atmospheric and Vacuum Towers.

- FCCU main fractionators & Light Ends Units.

- Reformate Stabilizer & Gas Plants.

- Petrochemical and Chemical Plants

- Ethylene Plants : C2, C3, C4 Splitters

- Butadiene

- BTX

- Ethylbenzene

- Acrylonitrile, Caprolactam

- VAM, VCM, EDC

- DMT, TPA, ANONE/ANOL

- Formic Acid, Acetic Acid

Benefits of ADV™ Trays

- Retrofitting exiting trays to ADV™ trays : Up to 40% increase in throughput at comparable unit energy cost.

- Equippin new towers with ADV™ trays : Up to 40% more capacity or up to 17% energy savings at no extra cost.

|

| TRAY |

|

| Packing & Internals |

|